Whyalla featured on hit documentary series Australian Story

In September 2018, the ABC’s hit documentary series Australian Story tracked ...

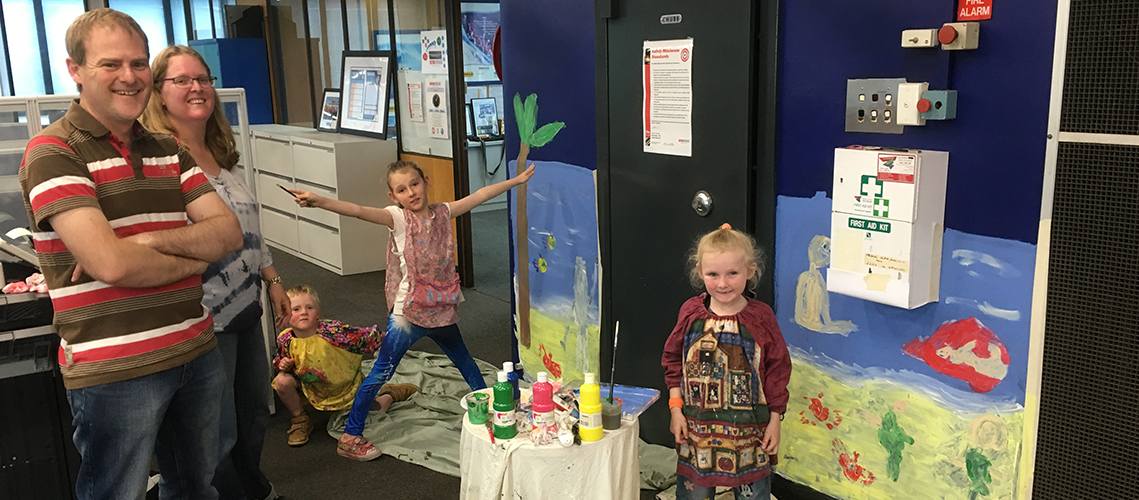

Mark and Michelle Whitehouse with kids Alice, Hannah, Jacob at the Mayfield family engagement day

A lot can change in three years with the right direction and support, and the results coming from our Mayfield Liberty Metalcentre branch prove it. In 2016, the site was struggling with safety and financial challenges, but after implementing turnaround strategies, Mayfield is now kicking goals – injury free with a strong financial performance.

Mayfield Metalcentre Location Manager, Mark Resevsky shared some of the strategies they undertook as a team.

In summing up what they’ve done at the branch, Mark said, “We have a vision for employees to follow, we’ve built a sense of trust and family, addressed our problems quickly, followed through on what we said we would do, and had some fun together along the way.”

The upgraded Quench & Temper Bar Mill at Laverton

Well done to the team at Laverton for delivering the Quench and Temper Bar Mill Upgrade Project in record time. The mill now produces a stronger 50mm DBar product, which reduces downstream material handling for our customers and provides a vital input into Victorian infrastructure projects.

Victorian Operations Manager, Hercules Van der Merwe said, “The team performed exceptionally well, delivering the project much earlier than planned. We’re now able to access new markets – key to the growth of our business.”

The $2.5 million project, which ran from February 2018-19 was not without its challenges. Negotiating shorter lead times with overseas equipment suppliers, the team achieved their target date ahead of time and are now producing new product on a 34-year-old plant.

Participants at the Whyalla Change Lab

We want to be known as the organisation that walks the talk, so it was great to see a group of employees at Whyalla actively embracing our value of ‘change’ to reimagine how we can work together more effectively.

Our first ‘Change Lab’ provided the opportunity for fresh thinking and input from a cross-section of our Whyalla workforce on better ways of working and how we can continue to build a thriving organisation for generations to come.

Grant Schmidt, General Manager of Culture and Performance, said the Change Lab was a very productive experiment.

“Not only did everyone in the room want change, but there was genuine alignment on what needs to change,” he said of the session, held late last year. “Major light bulb moments included consensus that everyone has the responsibility to be a change agent, and recognition that there’s a real opportunity to improve the way we work, however this is just the start. We found out that people in the room were a lot closer than any of us probably thought, but now it’s about taking it to the broader workforce to create a change movement.”

Australian rail workers

Each year in Australia almost one billion passengers take a rail journey and 1.5 billion tonnes of freight is moved. Rail passenger and freight demand is growing rapidly with investment set to exceed $100 billion by 2030.

This rail renaissance has provided Liberty with a unique opportunity to partner more closely with the sector. To maximise this opportunity a dedicated Rail Team has been created to focus on delivering customer solutions for rail operators, maintainers and governments across the country. The team brings together the Liberty Rail Sales and the EMRAILs business, reporting to Carol-Anne Nelson, with both brands maintaining a presence in the market.

This team is driving our capability and consolidating our position in this exciting and expanding market, growing both market share and product range in coming years.

L-R: Matthijs De Jong (General Manager, Liberty Metal Recycling Europe), Glen Schrader (Hexham Shredder Manager), Rod Langford (National WHSE Manager) and Bartosz Ruciński (Operations Manager, Liberty Metal Recycling Europe)

Bartosz Ruciński, Operations Director of our scrap collection and transhipment business in Gdansk, Poland visited Australia to experience our approach to yard operations and safety first hand.

“It’s great to see how such a big business operates, and how we can learn safer and improved ways of working from the Australian team,” Bartosz said.

The Gdansk branch is growing quickly, increasing scrap metal shipments from 2,000Mt every five weeks to 25,000Mt. With such rapid growth, it’s important the correct safety measures are in place. Some Australian safety measures introduced to the Polish business include; the installation of cameras, radio communications, and weighbridge systems to name a few.

Tahmoor South Project representatives gaining feedback on the project from local community members

The Tahmoor South Project is making strong progress on its promise to extend the operational life of the mine by an additional 15-20 years.

Now on exhibition to the public for comment, the ~$350 million project is on track for delivery by mid-2021, resulting in ongoing economic and employment benefits associated with the continued operation of Tahmoor Coking Coal.

Peter Vale, Tahmoor General Manager said: “It’s been as incredible team effort to get the project to this stage, with everyone in the project feasibility, technical and engineering, and environment and community teams really pulling together.”

The mine provides high-quality coking coal for steelmakers, with product going to Port Kembla for distribution to our Whyalla operations, and international customers.

Members of the Newcastle Austube Mills team with their kids at Family Day

The team at Austube Mills (ATM) Newcastle and Acacia Ridge share the many and varied reasons why they love working for the business. From the sense of family, to the variety involved in working for a growing business, hear from some of the employees below:

Gerald Darmanin (French Minister of Action and Public Accounts0 and Sanjeev Gupta (GFG Alliance Executive Chairman) at the Aluminium Dunkerque Inauguration

In the presence of the French Minister of Action and Public Accounts Gérald Darmanin, we formally welcomed Europe’s largest smelter into the GFG fold on 24 January 2019.

Situated in Northern France and producing in excess of 285,000 tonnes of primary aluminium each year, the business employs 570 people and has an impressive list of international customers in the automotive and packaging industries.

GFG aims to make the 570-worker plant the hub of an extensive manufacturing supply chain providing materials and components for French industry, particularly the automotive sector. Read more

L-R: Bert Downing (KCI CFO), Bob Beecham (Keystone Steel & Wire COO), Grant Quasha (GFG Alliance North American CIO), and Chris Armstrong (KCI CEO) at the KCI Inauguration

Our Executive Chairman Sanjeev Gupta visited the flagship Peoria, Illinois steelworks, following the acquisition of Keystone Consolidated Industries (KCI), to welcome over 1,000 US steelworkers to the global Alliance. Here he pledged to establish Liberty Steel USA as the country’s largest producer of wire rod within the next year.

Sanjeev disclosed that Liberty is already examining proposals to boost permitted liquid steel production at Peoria from 800,000 to 1.1m tonnes a year and, as part of its GREENSTEEL strategy, is exploring the potential to build a combined-cycle natural gas power plant on the site to cut carbon emissions by half, slash energy costs and enable further expansion of output from the site’s electric arc furnace (EAF).

In addition, Sanjeev announced that Liberty is looking closely at restarting the second EAF at Liberty Steel Georgetown, South Carolina, adding up to 500,000 tons of capacity there. Read more

Leave A Reply