Whyalla featured on hit documentary series Australian Story

In September 2018, the ABC’s hit documentary series Australian Story tracked ...

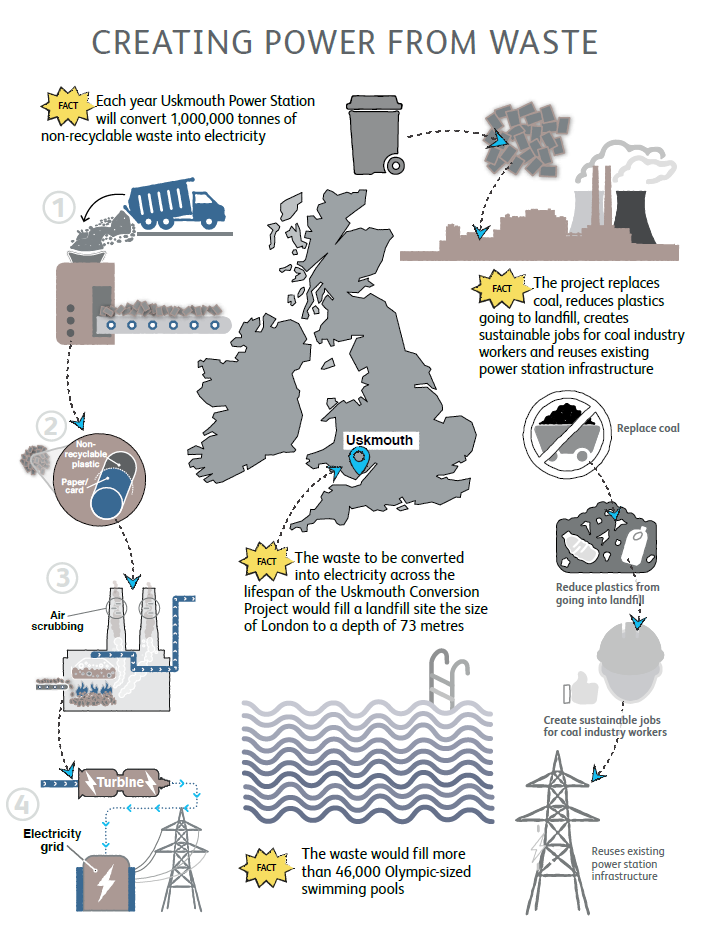

Pictured: The SIMEC Uskmouth Power Station

When it was designed and built in the 1950s, the SIMEC Uskmouth Power (SUP) station in the Welsh city of Newport was intended to be run on the area’s abundant local coal. Now, under an ambitious scheme involving SIMEC, the plant is being repurposed to run on another abundant resource: waste.

A plan by SIMEC Atlantis Energy Ltd will see the existing 363-megawatt (MW) coal-fired power plant at Uskmouth converted to a 220-MW plant that produces power by burning end-of-waste energy pellets. This represents one of the largest waste-to-energy projects currently under development in the UK.

The converted Uskmouth plant is intended to enter commercial operations in 2021 and will use pellets made from 50 per cent non-recyclable waste and 50 per cent biogenic material, such as paper and cardboard. In doing so, it will prevent more plastic from entering landfills across Britain.

The plant will sell all its power under a 20-year power-purchase agreement to Marble Power, a GFG Alliance company. It will be provided with fuel pellets under a proposed 20-year fuel-supply agreement with a joint venture company to be partly owned by SIMEC Energy and partly owned by Dutch recycling group N+P Group BV.

Atlantis Resources Limited acquired the Uskmouth power station in 2018. In return, SIMEC Energy acquired a 49.99 per cent share of Atlantis, which was then renamed SIMEC Atlantis Energy Ltd. SIMEC Atlantis Energy is listed on the London AIM stock exchange and has the stock ticker SAE.

Below, Tim Cornelius, CEO of SIMEC Atlantis Energy, answers some common questions about the SUP project and its environmental impact and benefits.

Is the Uskmouth Conversion Project another incinerator?

No, SUP won’t be an incinerator in terms of [Britain’s] main emissions legislation. SUP’s primary purpose is the generation of energy rather than the disposal of waste, and that’s what differentiates it from incinerators under this legislation. Energy-from-waste plants, on the other hand, derive much of their income from gate fees – their primary purpose is to dispose of waste and that’s where their income comes from. SUP is different – it buys its fuel rather than receiving gate fees for disposing of waste. It can afford to do this because of the high fuel quality and high efficiency of conversion, coupled with the low fuel price.

Further, SUP will be adhering to the best available techniques set out for large combustion plants, rather than for waste incinerators. This means meeting higher targets on efficiency, in particular. Most recent data from the Confederation of European Waste-to-Energy Plants indicates an average efficiency for electrical plants of less than 22 per cent, compared to an expected value of 33 per cent at SUP. This can be achieved because of the much more closely controlled input fuel; SUP will not be combusting raw waste and will instead use an energy pellet produced to a narrow specification using selected waste streams. Not only is the plant more efficient, but at 20MJ/kg the energy content of the pellet is much higher (approximately double) than traditional energy-from-waste plants. This means more energy out per unit of fuel in.

Whilst not essential, it’s the intention to seek end-of-waste status for the fuel as it meets the necessary criteria – being a new, useful product made to a particular specification and supplied to meet a market demand. End-of-waste status will ensure the plant is even more clearly differentiated from traditional energy-from-waste incinerators.

What is the emissions profile of this project?

The project is governed by the [European Union’s] Industrial Emissions Directive, and will adhere to all the applicable criteria set out in that legislation.

As approximately 50 per cent of the energy pellets will be made up of biomass-derived waste, this component is treated as CO2 neutral because of the net-zero lifecycle emissions of biomass. An added benefit is that this biomass waste does not end up in landfill, where it could otherwise decompose and release methane – a much more powerful greenhouse gas.

Is it clean energy?

It’s a sustainable approach which allows an extension of the useful life of an otherwise defunct asset, and recovery of useful and high-quality energy from materials which could otherwise end up in landfill (or being incinerated in less efficient facilities). It’s a shining example of the circular economy in action.

What a Fantastic way to dispose of Things ( Waste ) That Nobody has any use for and Turning it into a Reliable Source of Energy , Which Particularly Australia is Looking For .

Realise this is In Great Britian But Please Can we Do The Same Thing Here In Australia, we are Crying out For

Cheaper Electricity to Power our Industries , which is Driving Businesses to other countries.

Honestly this is one of the Best inavations that i have Seen in Years.