Whyalla featured on hit documentary series Australian Story

In September 2018, the ABC’s hit documentary series Australian Story tracked ...

Continuous improvement is core to what we do at GFG. This month we’re taking a look around the world to see what the local teams have be doing to continuously improve their business.

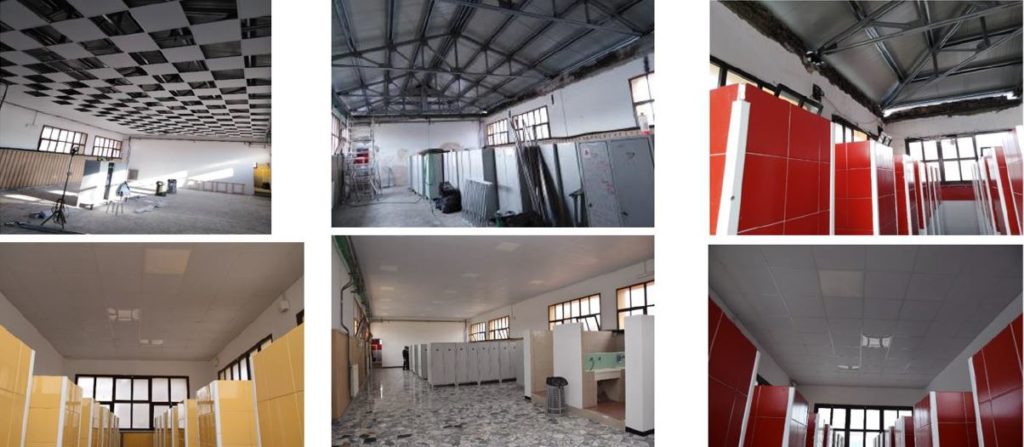

The team at LIBERTY Magona rallied together to raise a new roof last year – and they tackled the challenge with some fresh and innovative thinking.

The East Wing building, initially constructed in 1935, experienced a partial roof collapse last year. In keeping with buildings in the region, the East Wing’s roof has a reinforced brick structure, supported by sloping brick joists. But the engineering department, ever the innovative thinkers, took the opportunity to brainstorm an entirely new solution – and the result was functional, beautiful, and it’s made from our steel!

A lot of detail went into the planning – there were 15 galvanized trusses, perimeter walls were involved, false ceiling panels, and 600 square meters of painted sheet metal panels – but, as the saying goes, a picture tells a thousand words, so take a look at the incredible transformation and the impressive result.

Well done to the entire team on this beautiful and clever work!

Here’s an impressive story out of Piombino, and proof that in continuous improvement, everybody has a role to play:

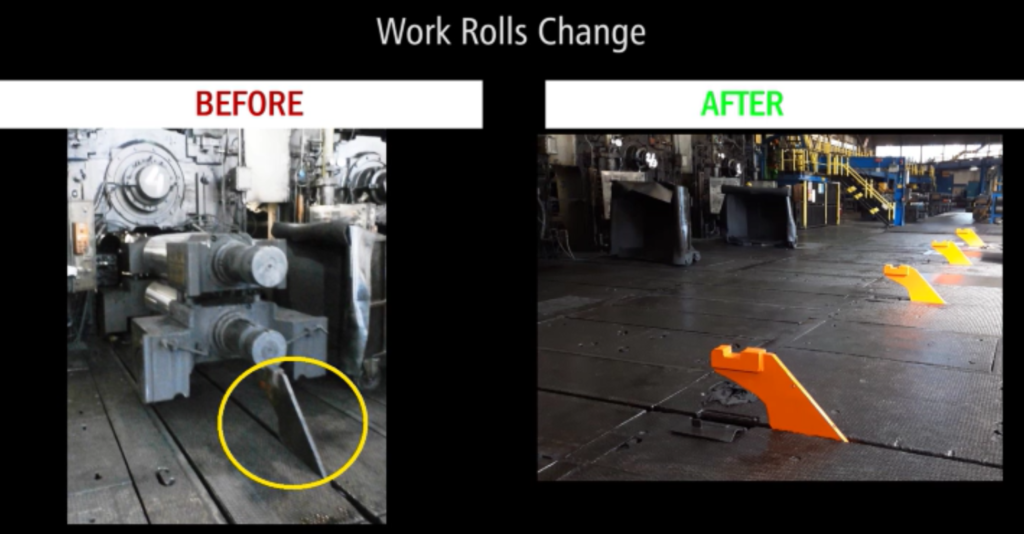

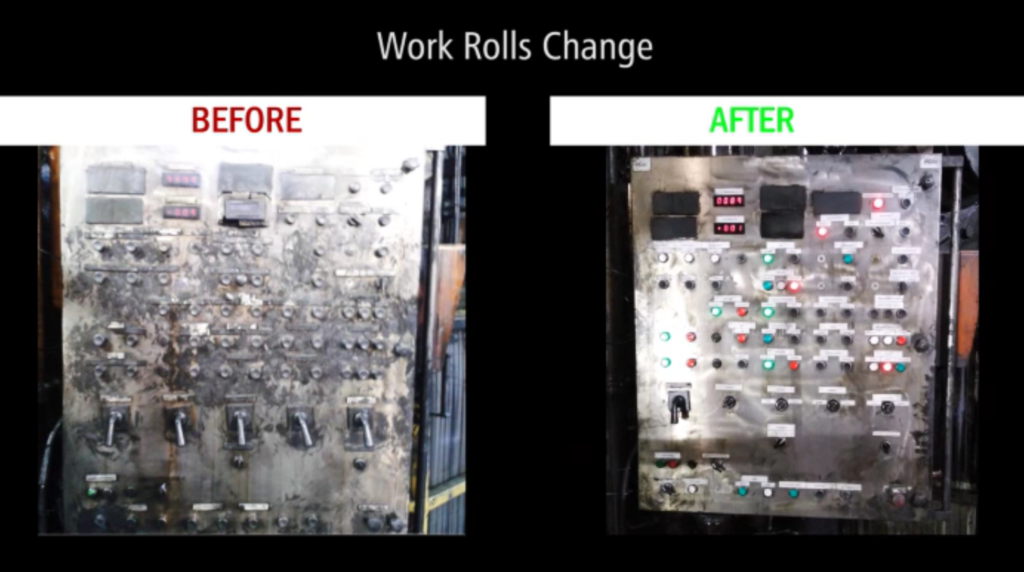

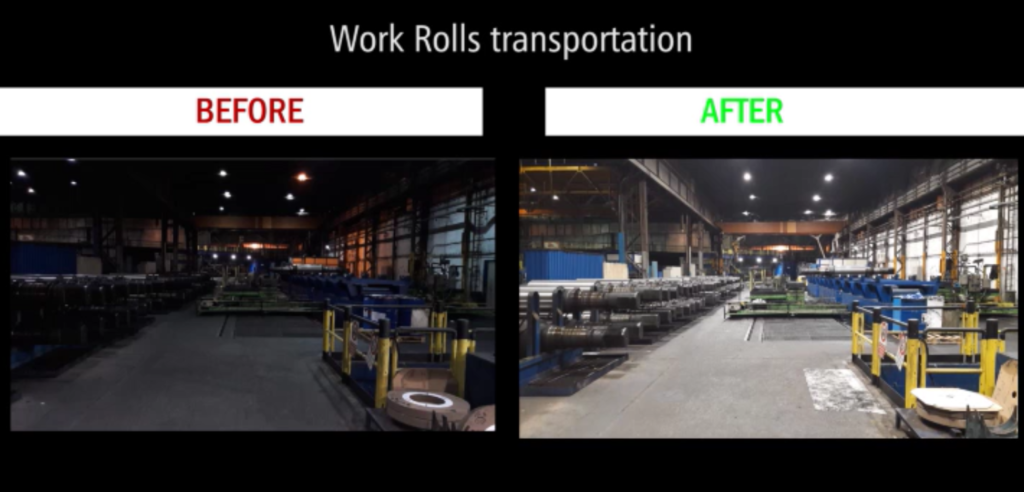

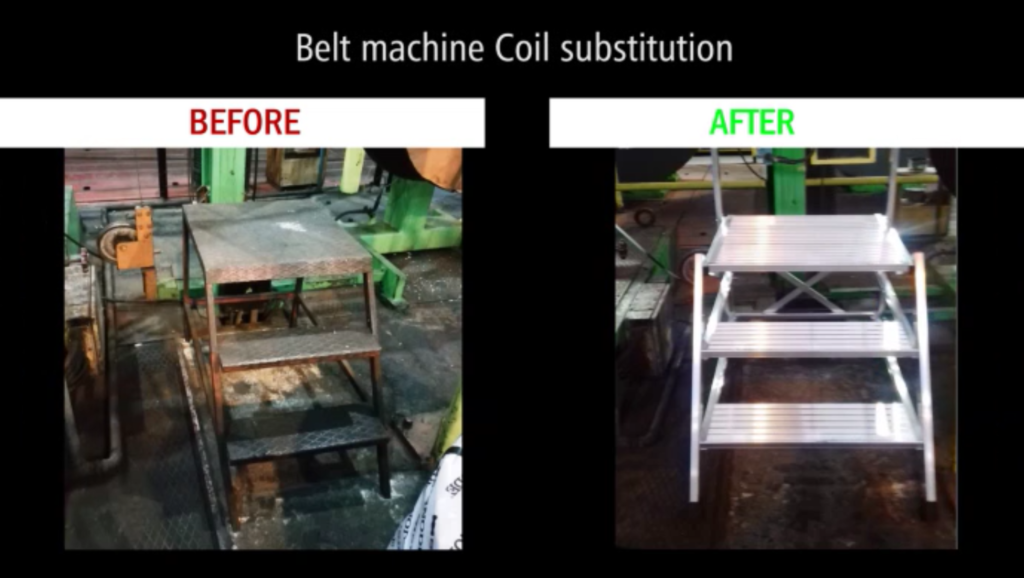

The team at LIBERTY Magona conducted a project designed to reduce risks, hazards, and potential for injuries in the Cold Rolling Mill.

One of the fascinating things they did was to film all teams completing their tasks at work. They filmed different teams from different shifts performing the same tasks. Then, they got the employees together and played all the videos back-to-back. This way, the various teams could see how others worked and could see how their colleagues often approached the work or did things in a different way.

As a group, they identified the pros and cons of each way of completing the tasks and discussed ways to improve collectively. This included agreeing on safety behaviours, and brainstorming ways to draw attention to potential hazards in their workplace.

The result? A bit of a makeover for Magona! As you can see in these photos, the team set about cleaning, clearing, and painting their part of the plant.

Overall, the project involved more than 40 people from a range of roles and departments working side-by-side. Together they made 75 proposals for change and implemented those effectively to reduce hazards. The feedback from the team was also incredibly positive, with employees feeling like they were part of the project and the solution.

Really impressive, and such a great way to draw attention to safety and to ensure that everyone can go home safely at the end of shift!

Leave A Reply