Whyalla featured on hit documentary series Australian Story

In September 2018, the ABC’s hit documentary series Australian Story tracked ...

Continuous improvement is core to what we do at GFG. This month we’re taking a look around the world to see what the local teams have be doing to continuously improve their business.

Red Brand is a division of LIBERTY Steel USA, and despite the global pandemic, 2020 was one of the best in the team’s 132-year history.

Key to the team’s success was truly understanding their customers and the role that Red Brand could play in solving problems. One of the innovations the team deployed was the Red Brand Fence Calculator.

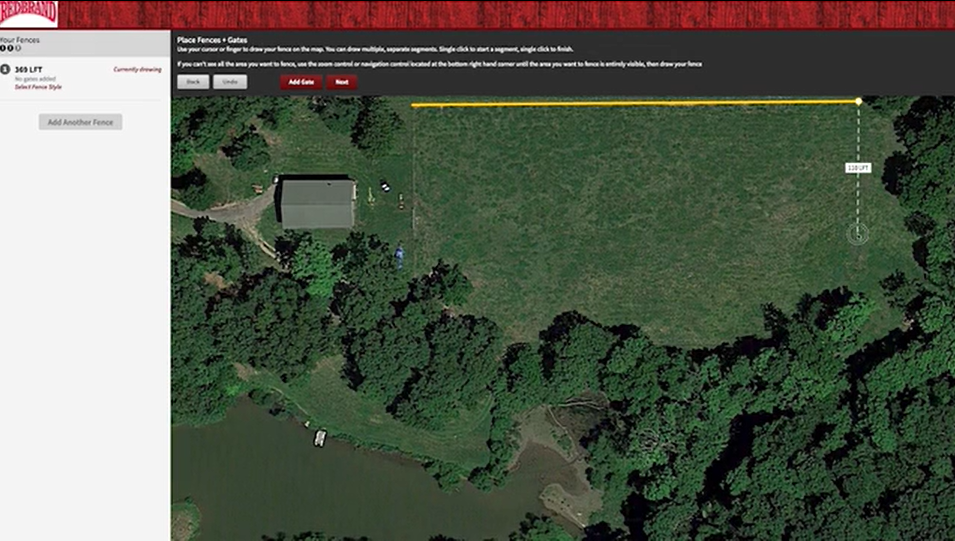

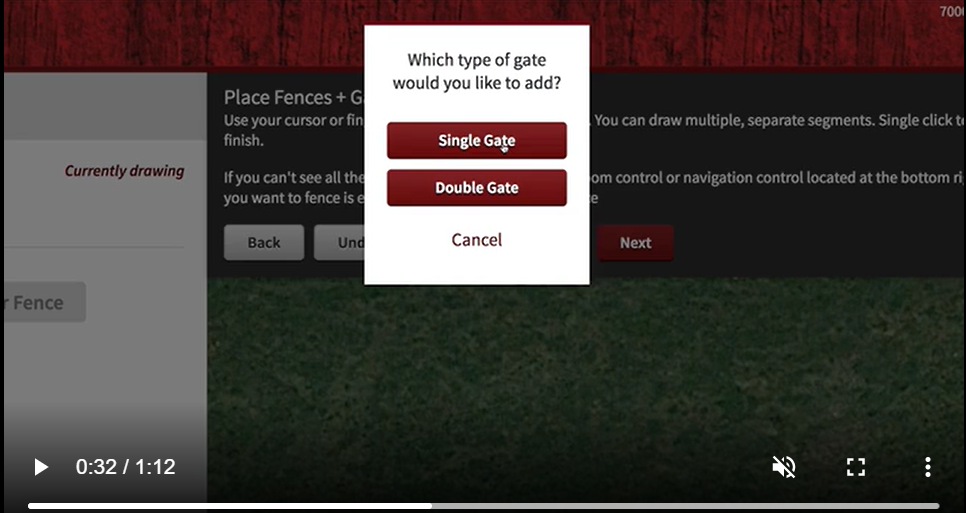

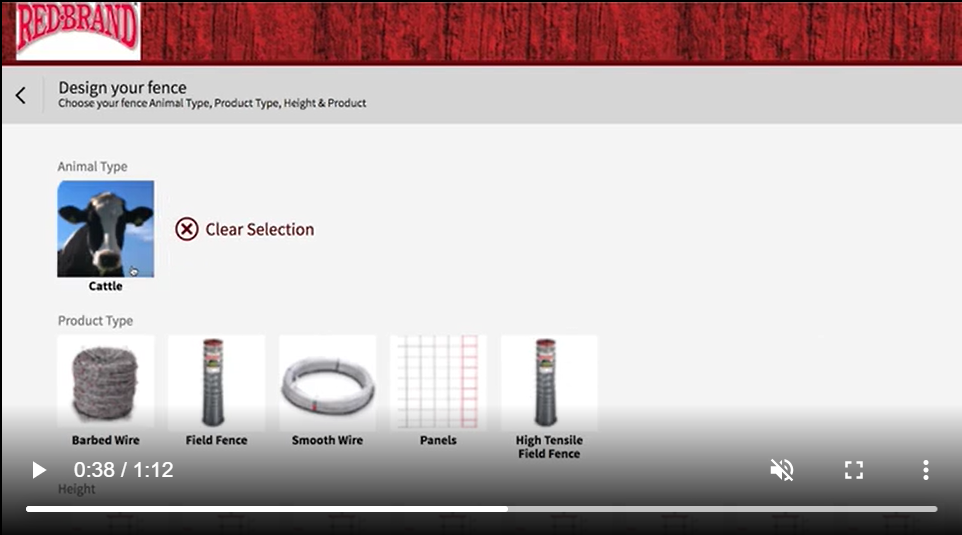

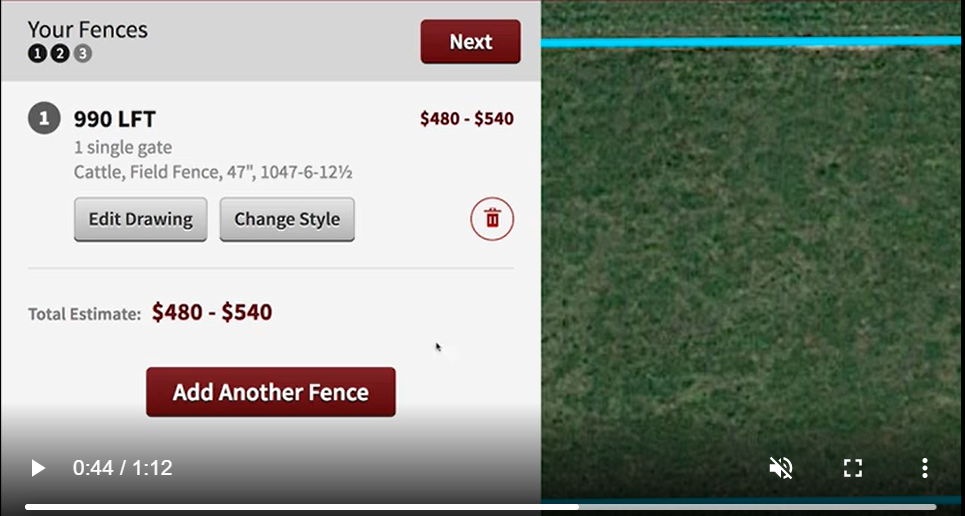

The Calculator, a free online tool, is a wholly unique solution for fence buyers – both retail and consumer. Intuitive and easy-to-use, the tool gives customers the ability to map out their fence using satellite images.

Users open the tool by visiting the Red Brand website, enter the address of their property to get a bird’s eye view of where they intend to build their fence. Then they can click and drag the parameters of their fence, select the kinds of gates or other features they think they’d like, and receive a materials list and pricing.

It’s a seamless experience, and the tool helps to position Red Brand into a class above other fence manufacturers.

The team’s latest innovation is a reminder that continuous improvement at it’s core, is about finding better ways to solve problems and complete tasks – whether that’s the operation at our own facility, or the experience for our customers – applying a continuous improvement mindset it what will keep our business on a path to success.

You can take a look at the calculator for yourself on the Red Brand website in the ‘Resources’ section. Nice work!

One of the benefits of embracing a continuous improvement mindset is that you start to think proactively about improvements that could be made across all areas – even safety.

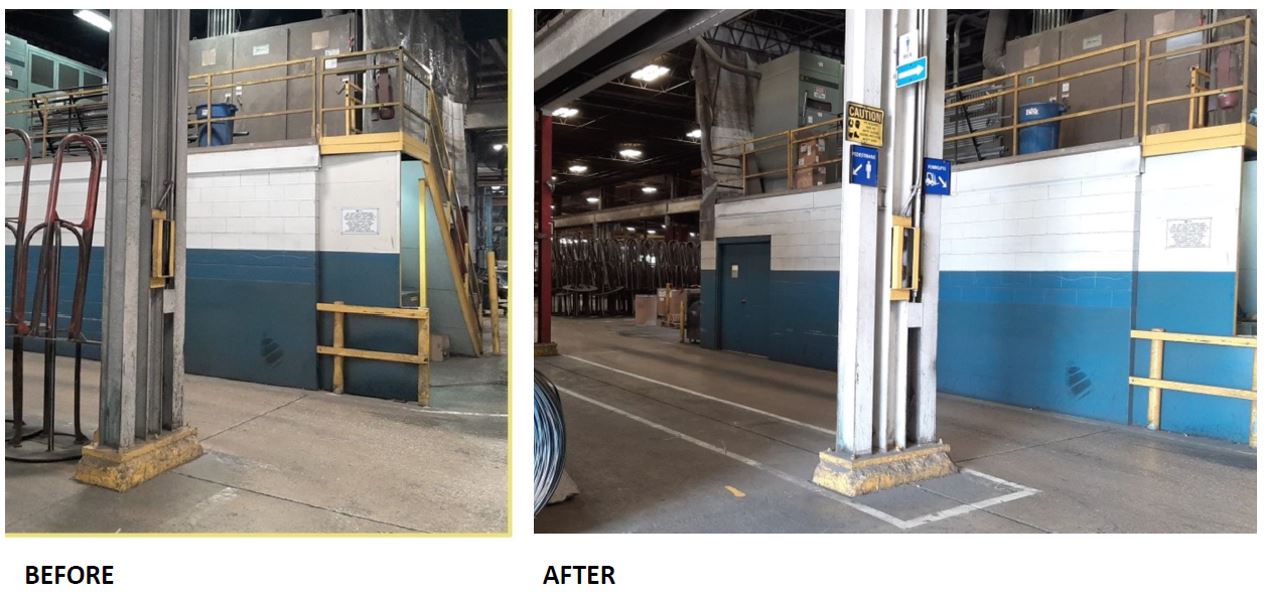

In Ohio, at the Upper Sandusky LIBERTY Engineered Wire Products, there was an aisle inside the plant that was designated for both pedestrian and forklift traffic. While the setup had existed for decades, there was a blind corner at the end of this aisle which led into another aisle.

One of the local team members, Vern Row, who has more than 20 years’ service under his belt, recognized the potential danger of this unsafe set up and proposed to reallocate storage space adjacent to the aisle for a pedestrian walkway.

As Bryan Say, the site’s Safety & Compliance Manager told us, “On the surface, this suggestion appears simplistic and basic. However, it provided a welcomed solution in alleviating a dangerous condition that could have become catastrophic.”

The result, as you can see in these pics, is that the local team is kept safe and the forklift drivers have no need to feel apprehensive traveling in the area.

Bryan also added that, “Safety change almost never occurs without a change in the culture. Vern recognized the risk to safety and strove for excellence, determined to look at things differently. By looking ‘outside the box’ of conventional wisdom he was able to see a new opportunity for improvement. Vern is a Life Saver!”

You haven’t seen the last of La Place! While it’s still very, very early on in the journey, their progress so far is incredibly encouraging, so we just had to bring you this update.

In January 2020 LIBERTY acquired the Bayou Steel business in Louisiana.

The site, which had been through a bankruptcy, featured a mothballed melt shop, rolling mill, and separate metals recycling business. Within weeks, LIBERTY nominees met on site and over just three days in March 2020 developed a restart plan for the Recycling business.

This plan covered all aspects of the operation, from safety to IT, employees to branding, legal and accounting, permits and environmental considerations, purchasing, sales, competitor response, operations – they covered it all!

On 14th May, LIBERTY Recycling La Place made its first purchases of Fe scrap metal.

In the very short time since, the business has exceeded its business plan and budget and for the six months to the end of the calendar year, generated a greater than 10% operating EBITDA %, and most importantly, achieved zero safety incidents.

Even better, the team achieved this outstanding outcome whilst managing the impacts of the COVID-19 pandemic.

As we said, it’s still early days, but it’s great to see how the team, when working side-by-side can find ways to continuously improve and bring a business back to the community.

Leave A Reply